Description

Polyurethane sandwich panels are polyurethane insulation sandwich panels for buildings, also known as leakproof sandwich roof panels, polyurethane rigid foam insulation panels, polyurethane composite panels, PU panels, etc.

Polyurethane sandwich panels are polyurethane insulation sandwich panels for buildings, also known as leakproof sandwich roof panels, polyurethane rigid foam insulation panels, polyurethane composite panels, PU panels, etc.

It is a widely used and potential energy-saving building envelope material. It is also a new energy-saving plate advocated and promoted by the Ministry of National Construction.The PU panel can be customized according to customers’ requirement of cold room temperature.

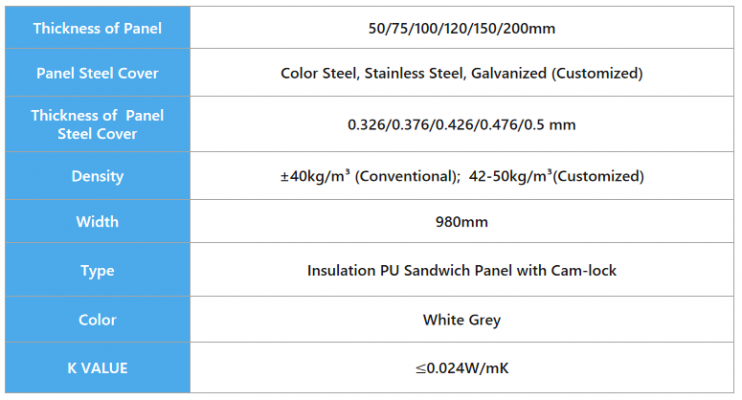

The panel thickness ranges from 50 mm-200 mm(50 mm,75 mm,100 mm,120 mm,150 mm,200 mm).Different surfaces are offered so as to meet different sanitary requirements and refrigerated goods’ requirements(PPGI,SISI,Embossed Aluminum etc.).

Cold room cold storage panels thickness usually made according to the room temp, and the sized can be customized.

Frozen meat storage is a scientific solution for preserving the perishability of meat foods. Meat foods lose their use value due to enzyme decomposition, oxidation and microbial growth and reproduction. Freezing can inactivate enzyme decomposition, slow down oxidation, and inhibit microbial growth. Make the meat food is dormant, and the original quality is maintained after several weeks or even months of product production before being consumed. Many countries have specified that frozen foods, manufactured goods and aquatic products must be transported at temperatures of -18 ° C or lower. Meat cold storage frozen meat products are: frozen meat, poultry, beef, lamb, pork, chicken, duck, goose, fish, seafood and other meat products.

Frozen meat storage is a scientific solution for preserving the perishability of meat foods. Meat foods lose their use value due to enzyme decomposition, oxidation and microbial growth and reproduction. Freezing can inactivate enzyme decomposition, slow down oxidation, and inhibit microbial growth. Make the meat food is dormant, and the original quality is maintained after several weeks or even months of product production before being consumed. Many countries have specified that frozen foods, manufactured goods and aquatic products must be transported at temperatures of -18 ° C or lower. Meat cold storage frozen meat products are: frozen meat, poultry, beef, lamb, pork, chicken, duck, goose, fish, seafood and other meat products.

The cold storage is a warehouse creating the suitable humidity and cold condition with the use of cooling facility which is also known as the refrigerated storage. It is a place to process and store the products. It can get rid of the influence of the climate , prolong the storage period of various products to adjust the market supply.

cold room solutions is mainly used for the constant-temperature storage of food, dairy products, meat, aquatic products,poultry, fruit and vegetable, cold drink, flower, green plant, tea,medicine, chemical raw material, electronic instrument, etc.We would like to provide you best one-stop solutions.

Package and transportation:

Each PUF panel is well wrapped with plastic film respectively,each corner use hard kraft paper wrapped well. Both the LCL and FCL shipping , we all use plywood box with wood pallet on the bottom,sturdy packaging to protect the machine.

FAQ:

Q: What key information should I provide the supplier?

A: Room size: Length*Width*Height?

What kind of goods will put into the room (fresh or frozen)?Which country will you build the project? What’s the temperature in summer over there?How about voltage?

Q: Can the power supply be single phase?

A: Single phase electricity is not applicable. It need the industrial supply electricity for the whole plant, that is to say it needs 3 phase electricity, 380~420V/50Hz/3P or 220~240V/ 60Hz/3P, or other types.

For special power supply type, we will design a special motor for you. So please kindly tell me your local industrial power supply when you send the inquiry, we will offer you based on the exact requirement.

Q: Do you make testing and commissioning before you deliver the machine?

A: Yes, all of our machines will be tested and commissioned at least 3 days to ensure sufficient output and stable performance before delivery. When you get the machine, you just need to connect water and power supply.

If you enquire cold room, please kindly confirm the following information:

1. what your cold room is used for?

2. what room temperature you required for?

3. what the cold room dimension is or how much food or other products will be put inside?

Please kinldy confirm the above information and we will reply you as soon as possible.